Description

The Dini Argeo Pallet Truck Scale – Hygienx

The TPWI HYGIENX is a stainless steel pallet truck is ideal for food, chemical, and pharmaceutical sectors. Especially for wet environments demanding high hygiene. With it’s 100% AISI 304 stainless steel pallet truck, It can be fully sanitized with high-pressure water jets without risk of damage or corrosion.

The Dini Argeo Pallet Truck Scale, Hygienx has non-toxic hydraulic oil making it safe for the food industry. Equipped with 4 IP69K-certified stainless steel load cells. The rechargeable battery lasts up to 100 hours and the IP69K stainless steel weight indicator is waterproof, easy to clean, and durable. Featuring a 25mm high-contrast LCD display for low light. Each pallet truck is tested and certified for accuracy.

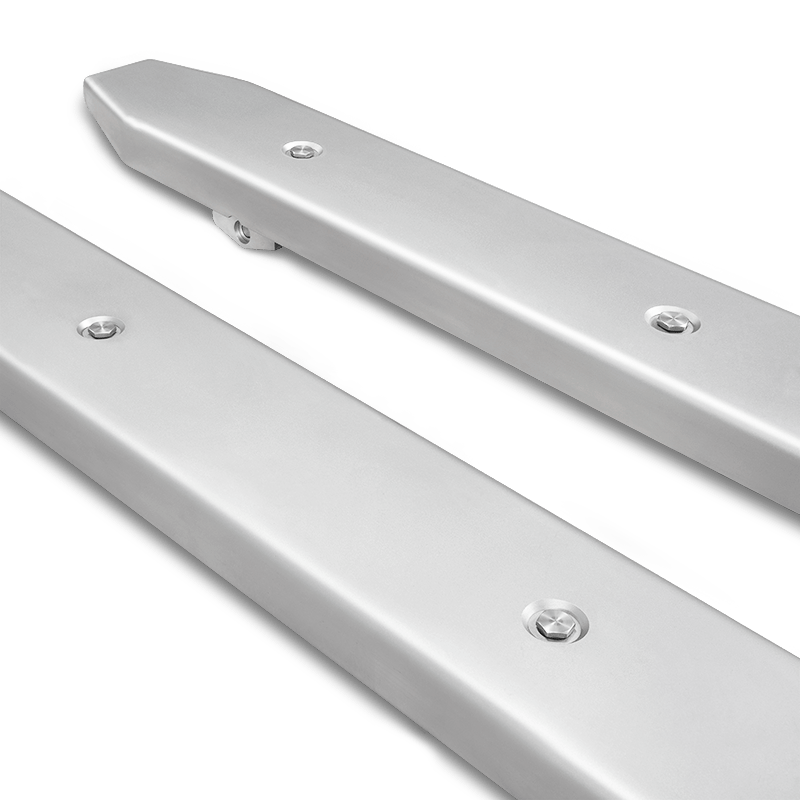

- Fork dimensions: 1180 x 550 x 85 mm

- Waterproof membrane keypad featuring 17 numeric/functional keys

- Lift pump made from AISI 304 stainless steel for controlled fork lowering

- Battery charging socket with dual protection against water and humidity

- Constructed entirely from AISI 304 stainless steel

- Steering wheels with a diameter of 200 mm

- Lowered profile forks with a height of only 85 mm

- 230Vac 50Hz battery charger with standard EU plug

- Removable fork covers for easy inspection and cleaning

- Approximate weight: 135 kg

- IP68 watertight column

- Operating temperature range: -10° to +40°

- Nylon steering wheels and double loading rollers with polyurethane coating

- Lifting height of 200 mm

- Configurable RS232/C bidirectional port for PC, radio module, WIFI, or handheld terminal

Feefo 5.0* 1000+ reviews

Feefo 5.0* 1000+ reviews UK wide delivery on all products

UK wide delivery on all products Products can be fully calibrated & certified

Products can be fully calibrated & certified Service & repairs at competitive prices

Service & repairs at competitive prices Find a better price and we will try and beat it

Find a better price and we will try and beat it

Reviews

There are no reviews yet.